New challenges need new technologies

Our wide-ranging exposure to process technologies and diverse industry challenges has driven us to develop new technologies which can generate alternative products, open new markets and improve processing efficiencies.

Our research and development program involves collaboration with universities, research organisations and private industry. Current active R&D projects include:

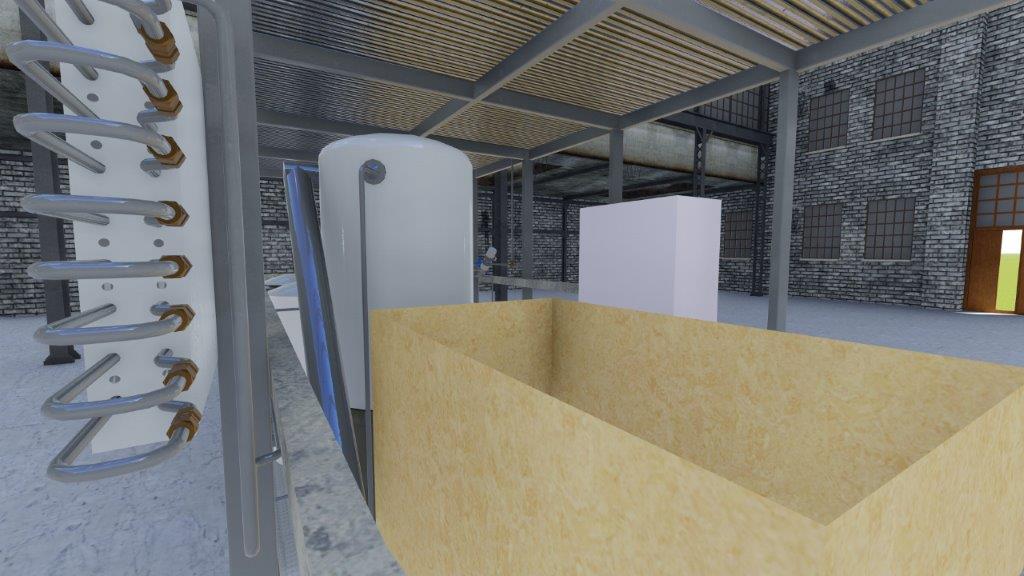

Oil Extraction

Enerbi is developing a new solvent extraction method to remove high value commodity oils and essential oils from organic substances at room temperature. Preliminary results indicate that this technology can deliver a significant reduction in the cost and scale required of solvent oil extraction using a non-toxic, non-carcinogenic solvent. We are currently in the process of designing and building a pilot plant to undertake further testing on a wide variety of feedstocks.

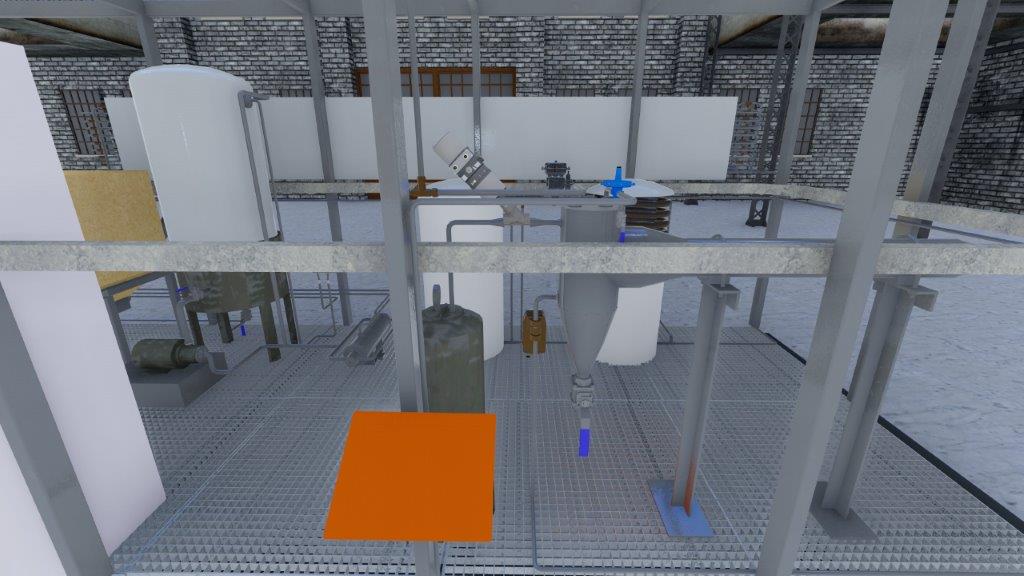

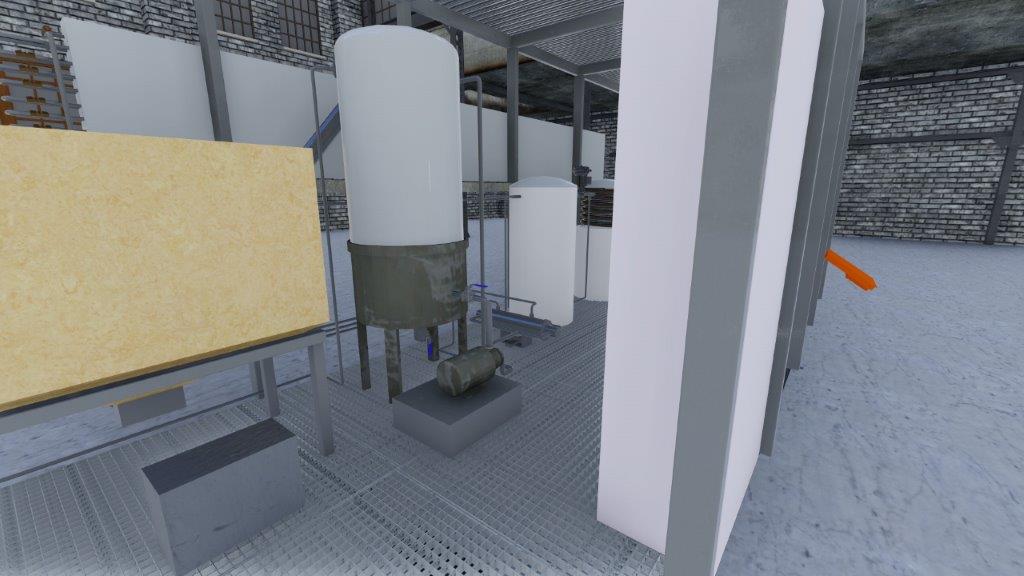

Hydrothermal Processing

Enerbi is working with Murdoch University to design and build a hydrothermal liquefaction pilot plant. This process can convert wet and solid waste into gases and liquids that can be converted to energy and chemicals. This plant will provide a platform for the testing of process improvements developed by Enerbi for pressure and heat recovery and utilizing by products.

Biomass Fired Zero Liquid Discharge Desalination

The growing challenge of dryland salinity has driven us to develop a desalination solution that results in zero liquid waste (saltwater brine) from inland brackish water sources. This technology can achieve 85% recovery of fresh water from brackish groundwater or surface water sources in inland environments. This technology has the potential to generate new sources of fresh water in areas prone to salinity. This can lead to low cost water sources that can replace expensive pipe networks and also potentially long term salinity reversal.

Heat and Power Solutions

Enerbi is developing a suite of combined heat and power technologies that have the potential to achieve step-change reductions in capital and operating costs. These systems also produce valuable bio-char and are based around turbomachinery solutions for long term reliability. These technologies will cover electrical generating outputs from 100kW to 10MW and thermal capacity of 300kW to 30MW.